- 2 Esdras 6:22 And suddenly shall the sown places appear unsown, the full storehouses shall suddenly be found empty:

Pork Shortages To Strike America In Two Weeks

We have some troubling news developing deep inside America’s food supply chain network, suggesting rapid food inflation could be dead ahead.

In the last several weeks, six major US meatpacking facilities have shuttered operations because of the coronavirus outbreak. That means 15% of America’s hog-slaughtering capacity has been shifted offline, and there is an additional risk that beef and poultry capacity could be reduced in the weeks ahead, reported Bloomberg.

With every virus-related plant closure, farmers have been denied access to meatpacking facilities/slaughterhouses, resulting in herd overcapacity and suggests euthanizing hogs could be next.

Dennis Smith, a senior account executive at Archer Financial Services, warned that “meat shortages” will occur “two weeks from now in the retail outlets.” That means by the first week of May, certain pork products could be out of stock at grocery stores across the country.

“There is simply no spot pork available. The big box stores will get their needs met, and many others will not.”

Cold storage facilities only have a few weeks to cushion supply disruption of the latest plant closures. Bob Brown, an independent market consultant in Oklahoma, said cold storage supplies have a little more than a week’s worth of production – and wouldn’t be sufficient in satisfying demand.

We noted on Wednesday Tyson Fresh Meats, the beef, and pork subsidiary of Tyson Foods, released a statement that said its top producing pork plant in Waterloo, Iowa, will suspend operations until further notice because of virus-related issues. For similar reasons, Hormel’s Rochelle Foods closed its plant last week. Outbreaks have also forced closures for JBS SA in Minnesota and Colorado and Smithfield Foods Inc. in South Dakota. Several other meatpacking plants have recently come back online from virus-related shutdowns.

“It means the loss of a vital market outlet for farmers and further contributes to the disruption of the nation’s pork supply,” Steve Stouffer, head of Tyson Fresh Meats, warned on Wednesday.

If plant closures like these continue, it could add additional strain on the supply chain and cause “weird dislocations for prices — finished products are surging, while farmers are getting paid much less for animals,” Bloomberg notes.

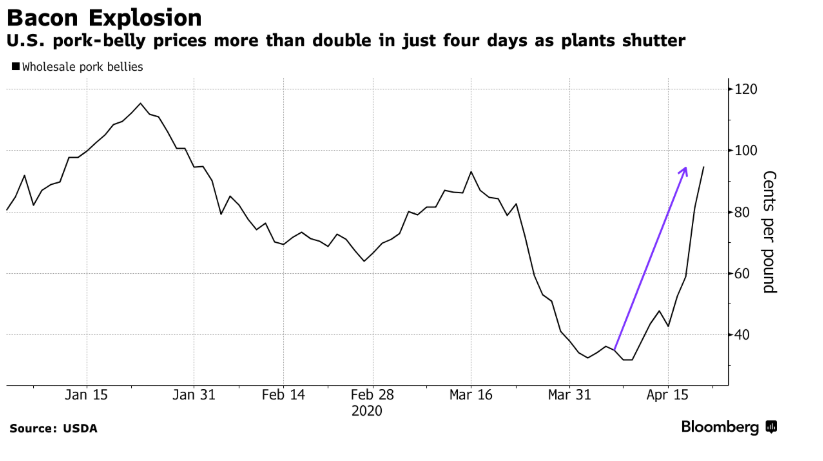

The chart below shows how meatpacking plant closures have triggered exceptional food price volatility for pork-belly prices — crashing in March, to now doubling in a few days.

“Prices for pork bellies, the cut that’s turned into bacon, have more than doubled in just the four days through Tuesday on supply concerns. With so many fewer hogs moving through slaughter, Smithfield Foods had to shutter facilities in Wisconsin and Missouri that turn pork into finished products like bacon and sausage.

Meanwhile, prices for the hogs themselves are plummeting. There are way more pigs than can be processed right now, so animals are backing up on farms. Hog futures traded in Chicago are down about 21% in April.”

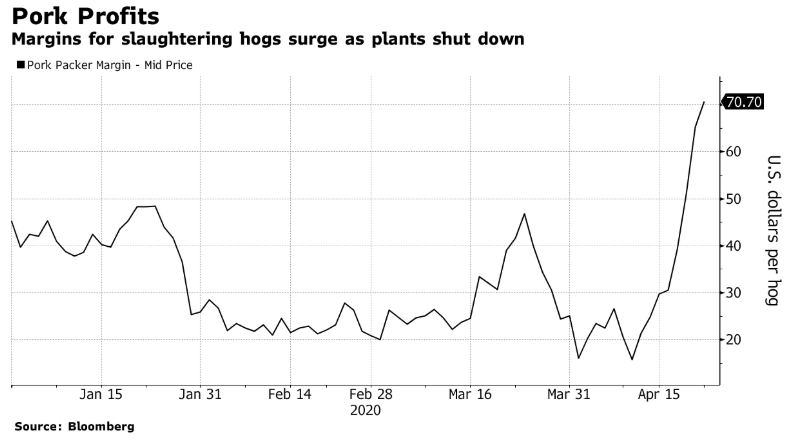

As for meatpacking plants, these folks are getting hogs at reduced prices from farmers and turning around and selling finished products to supermarkets for hefty premiums. HedgersEdge shows pork margins have jumped 340% since April 1.

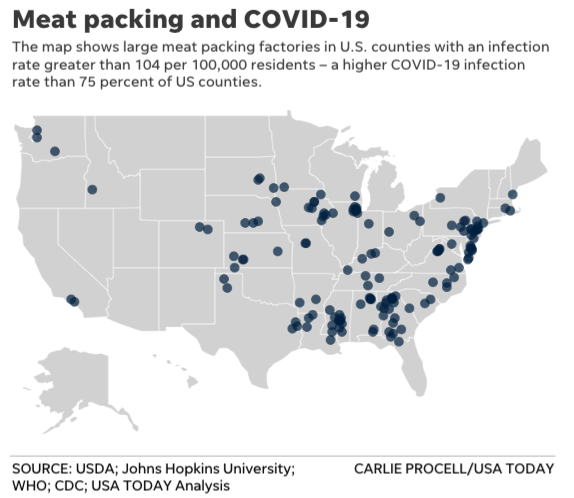

A USA Today report warns of a “rash of coronavirus outbreaks at dozens of meatpacking plants across the nation is far more extensive than previously thought:”

“More than 150 of America’s largest meat processing plants operate in counties where the rate of coronavirus infection is already among the nation’s highest, based on the media outlets’ analysis of slaughterhouse locations and county-level COVID-19 infection rates.

These facilities represent more than 1 in 3 of the nation’s biggest beef, pork and poultry processing plants. Rates of infection around these plants are higher than those of 75% of other U.S. counties, the analysis found.

And while experts say the industry has thus far maintained sufficient production despite infections in at least 2,200 workers at 48 plants, there are fears that the number of cases could continue to rise and that meatpacking plants will become the next disaster zones.”

And if meatpacking plants become the next disaster zone for the virus – resulting in the closure of more plants, then food shortages could materialize and or a rapid surge in prices, a combination that could leave millions angry at a time when an economic depression is unfolding. Food shortages could trigger social unrest…